With increasing pressure on supply chain leaders to implement technological responses to disruptions, supply shortages and security incidents, Gartner, Inc. has identified the top 8 supply chain technology themes in 2022. Gartner analysts have selected the themes for their potential to deliver automation, intelligence and resiliency.

According to a Gartner survey among 211 supply chain professionals in December 2021, 34% of respondents said that adapting to new technology is the most important strategic change supply chain organisations will face five years from now,” said Dwight Klappich, vice president analyst with the Gartner Supply Chain practice.

“Supply chain leaders must take multidisciplined approaches for identifying innovative technologies and orchestrate the right technology investments at the right place and the right time.”

Gartner analysts are discussing the challenges and opportunities of supply chain technology adaptation at Gartner Supply Chain Symposium/Xpo, taking place in Orlando through today.

The top supply chain technology themes in 2022 are:

Hyperautomation 2.0

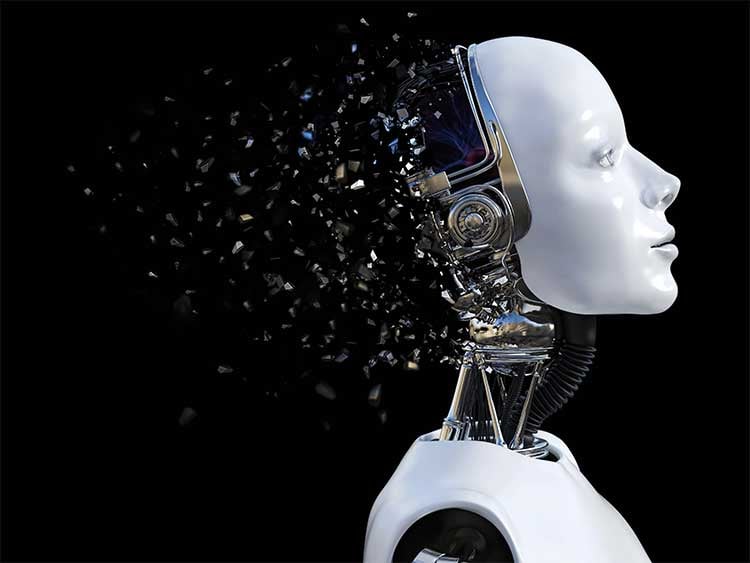

Hyperautomation is a business-driven approach that organizations use to rapidly identify, vet and automate as many business and IT processes as possible through the orchestrated use of multiple technologies, such as artificial intelligence (AI) and machine learning (ML). Hyperautomation 2.0 goes past this initial focus on AI and ML and integrates other technologies and tools of the technology portfolio.

During the next five years, hyperautomation 2.0 will be part of initiatives in warehousing, transport, production and others. Solutions will include intelligent remote fulfillment networks in warehouse or yard management domains and personalized e-commerce applications.

Next Generation Robots

Enterprise-centric next-generation robots are rapidly moving from the science fiction space to real-life production platforms, transforming a wide range of industries. These robots are more flexible and adaptive and now can be applied to a variety of tasks. In the future, companies will have heterogeneous fleets of robots where work will have to be orchestrated across different robots — meaning that robots have to interact with each other and need to communicate with other types of automated equipment like elevators and doors.

Autonomous Things

Autonomous things, such as robots, vehicles or drones can augment traditional manually intensive physical tasks with greater efficiency, clarity and safety. Working independently or in networks they also enhance a new generation of immersive work and customer experiences through enhanced service efficiency and transparency. Autonomous things support safer, more efficient and optimized processes and operations across supply chains.

Digital Supply Chain Twin

The digital supply chain twin (DSCT) is a digital representation of the physical – often multienterprise – supply chain. It is the basis for local and end-to-end (E2E) decision making that ensures that all decisions are aligned horizontally and vertically throughout the supply chain. Through its connection to the real world, situational awareness is greatly enhanced, and decisions can be made faster and more accurate.

Analytics Everywhere

Analytics are capabilities that deliver reporting, interactive data visualization, advanced analytics and intelligence — including ML and predictive and prescriptive analytics. With the ever-growing availability of data, AI can now be applied to transform data into information and deeper insights as part of a DSCT.

Security Mesh

Security mesh is a structured framework of governance, collaboration and applied technology applications that are orchestrated from within supply chains with the aim of ensuring supply chain systems, tools, applications and people are safe and secure at all times.

“Security in supply chains is only as strong as its weakest link,” Klappich said. “Security mesh embraces the reality of dynamic, interconnected and increasingly digitalized supply chains by addressing an evolving nexus of threats posed by cyber, digital and data.”

Ecosystem Collaboration

Ecosystem collaboration tools are digital technologies and services that create a collaborative work environment for people and generates new and continuous shared value opportunities. The pandemic has revealed to supply chain leaders that many supply chains don’t have basic communications or digital connectivity in place with key stakeholders, such as multi-tier supply networks or packaging networks – which has ramifications on decision making.

Ecosystem collaboration solutions and services establish foundational network visualisation and mapping tools to support continuous maturity in advancing to real-time digital connections across people, data, machines, systems, processes and things.

Sustainability Tools

Sustainability tools are an evolving spectrum of applications, services and capabilities that support events associated with directives for sustainability, environmental and circular economy impacts and mandates. They enhance levels of digitalization, collaboration and visibility, which is often crucial to formalize the processes and management disciplines needed for a progressive evolution of sustainability programmes.

“Sustainability has impacts that span the entire value chain — from plan, to source, to make, to deliver, to the service domain. Supply chain leaders who don’t invest in tools that support a wide range of sustainability goals and metrics risk a significant impact on brand, company image and consumer value perception. There’s also a risk of stranded assets, vulnerability to carbon tax, unpreparedness for climate-related supply chain disruptions – and accordingly shareholder value,” Klappich concluded.